Mursix Acquires Aul Brothers Tool And Die

Mursix is excited to announce the acquisition of Aul Brothers Tool and Die. Learn how the acquisition will expand Mursix's capabilities.

New 600-Ton Servo Press Positions Mursix Corporation for Growth

Mursix Prioritizes Staying Competitive for Customers by Investing in the Future Through Acquisition of Capital Investments

Purdue Data Mine Team Works with Mursix on Real-World Supply Chain Issues

A group of students at Purdue University recently analyzed supply chain issues at Mursix Corporation as part of a comprehensive, year-long program, offering recommendations for how the company can improve overall s...

Conexus Case Competition Provides Fresh Perspective for Process Improvements

During the Conexus Indiana National Case Competition students collaborated to solve real problems from today’s advanced manufacturing and logistics market. Learn more.

Mursix Awarded Grant to Advance Digital Thread Capabilities For Automotive, Medical, and Military Applications

Mursix is awarded a $250,000 grant to enhance the properties of Mursix's digital thread capability for future commercial automotive, medical, and military applications.

Mursix Adds Horizontal Injection Molding To Capabilities

Customers rely on Mursix for its continued portfolio of service offerings. With the latest addition of a new Nissei FNX180 injection molding machine, Mursix will be taking on even more diverse projects from custome...

Mursix Receives Help to Manufacture Medical Components for the Country

Manufacturers pivoted to medical supplies and components in the pandemic's wake. Indiana awarded grants to several manufacturers to help companies continue to innovate and keep current with demand.

Mursix Presents Project To Solve Issues in DoD Supply Chain

Mursix partnered with four other Indiana-based companies to pitch a pilot project to solve very difficult technical challenges faced by the DoD supply chain.

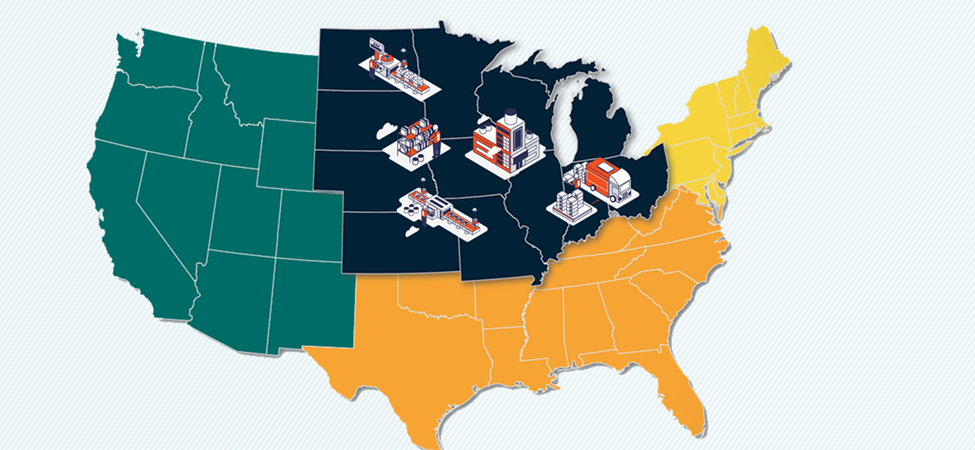

Benefits of Reshoring to Midwest Manufacturing

Decades ago, the idea that manufacturers would reshore back to the U.S. seemed like a pipe dream. With companies weighing the advantages of producing in the U.S., reshoring to rust belt cities is no longer a f...

Reshoring Manufacturing for Medical Supplies

The government is encouraging manufacturers to expand production to produce critical supplies within our own borders to combat shortages. Mursix has stepped up to help produce life-saving medical components and fac...